Comparison between AOB and GOB technologies

Table of Contents

Key Points

- Research suggests our company’s LED displays all come standard with AOB (Admixture on Board) technology, enhancing durability and reliability, so customers can feel confident purchasing.

- AOB involves applying a resin layer to strengthen LED and PCB connections, improving impact resistance by six times and environmental protection.

- Compared to standard SMD displays, AOB displays seem more durable, with better visual quality, smaller pixel support, and wider viewing angles (140° vs. 170°).

- An unexpected detail is that AOB reduces the LED defect rate to less than 5 parts per million, significantly lowering maintenance costs.

Introduction

LED displays are essential for modern visual communication, used in advertising billboards and public information screens. As demand grows for higher quality and durability, advanced technologies like AOB (Admixture on Board) have emerged to meet these needs. We’re proud to announce that all our LED display products now come standard with AOB technology, ensuring customers can purchase with confidence.

What is AOB Technology?

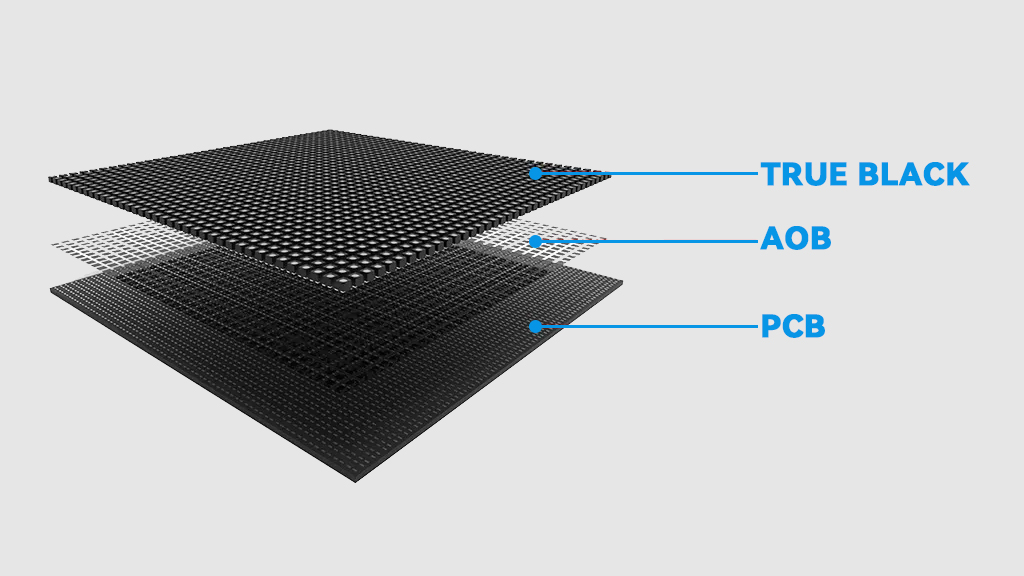

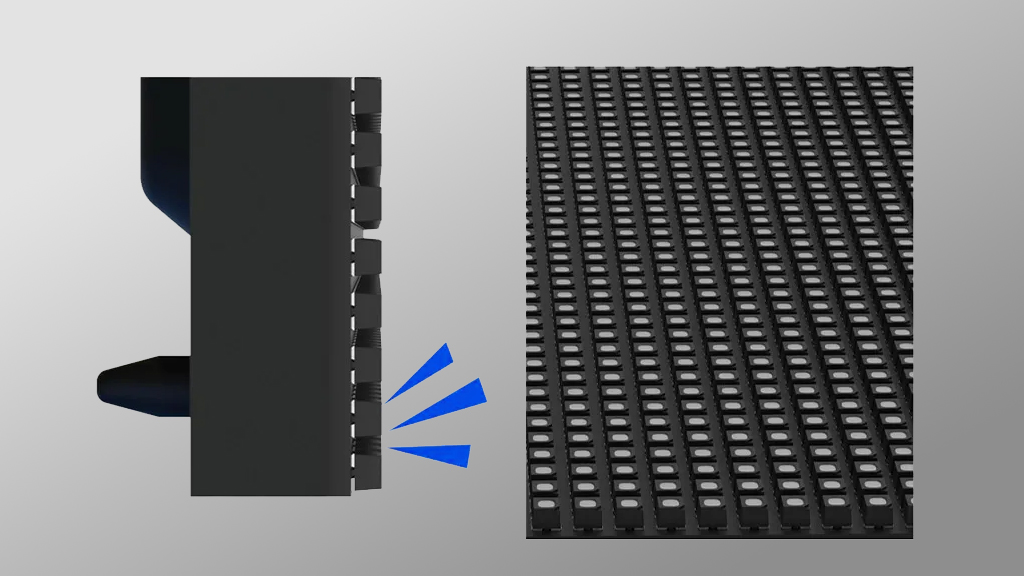

AOB technology applies a protective resin layer between the LEDs and the PCB, strengthening their bond. This process is the final step in SMD manufacturing, involving:

- Installing and soldering LEDs onto the PCB.

- Conducting 72-hour tests to ensure color balance and uniformity, fixing any defects.

- Spraying a polymer resin layer to fill spaces between LEDs, enhancing protection.

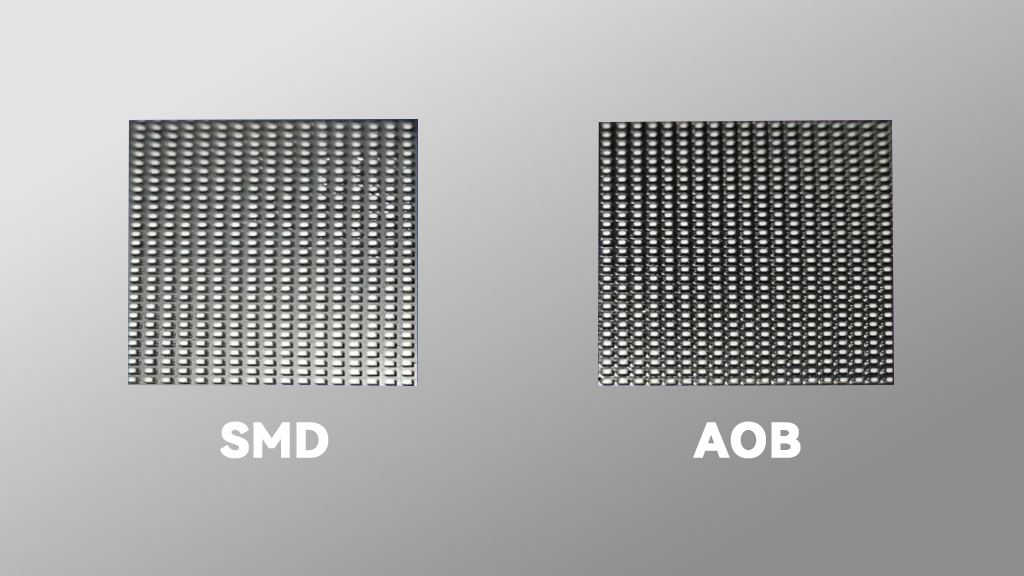

Visually, AOB displays show a matte, translucent black resin layer between LEDs, improving contrast and aesthetics.

Comparison with Standard SMD Displays

Standard SMD (Surface Mounted Device) displays mount LEDs directly on the PCB, but they lack the resin layer, making them more prone to damage. AOB displays offer:

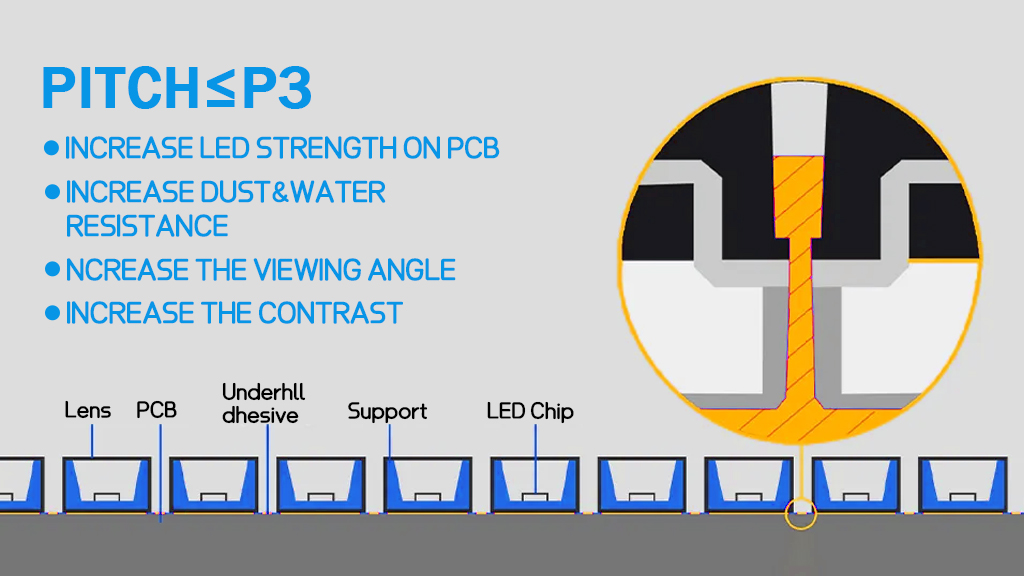

- Durability: Six times better impact resistance, with side push strength increasing from 1kg to 6kg.

- Design Flexibility: Support for smaller pixel pitches and wider viewing angles (170° vs. 140° for SMD).

- Visual Performance: Enhanced contrast and color consistency, ideal for high-end applications.

- Reliability: Defect rate reduced to below 5 PPM, lowering maintenance needs compared to higher rates in SMD.

Here’s a detailed comparison:

| Feature | Standard SMD Display | AOB Display |

| Impact Resistance | Low, 1kg side push, prone to physical damage | High, 6kg side push, 6x stronger |

| Environmental Protection | Basic, vulnerable to water and dust | Excellent, sealed, suitable for outdoors |

| Pixel Pitch Support | Limited, hard to achieve small pitches | Supports smaller pitches, high resolution |

| Visual Quality | Good, but lower contrast and color consistency | Enhanced contrast, better color accuracy |

| Defect Rate | Higher, more maintenance needed | Below 5 PPM, high reliability, low cost |

| Viewing Angle | Standard 140° | Increased to 170°, wider view |

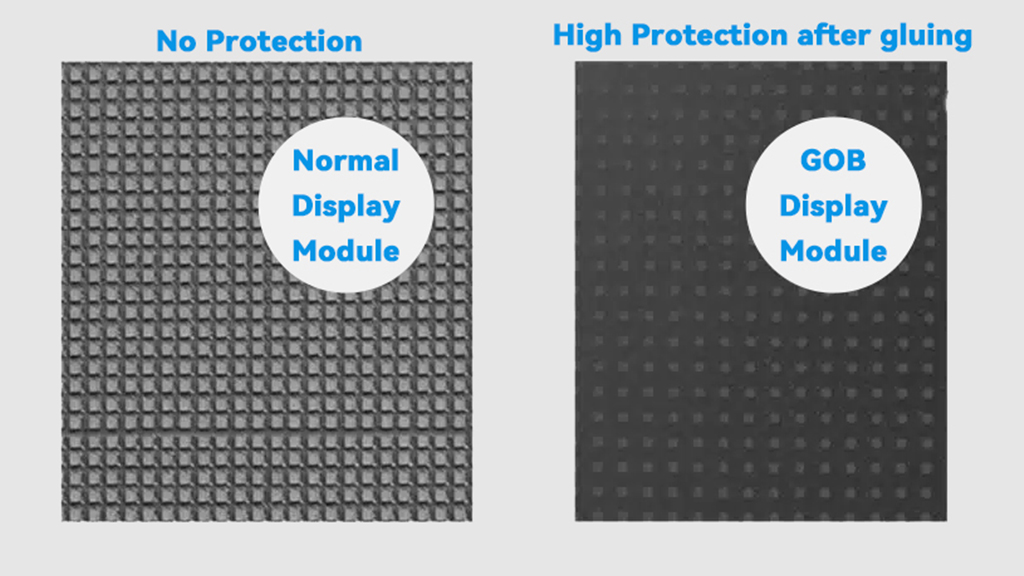

Visual Differences

AOB displays feature a matte black resin layer between LEDs, enhancing protection and contrast, while standard SMD displays have exposed LEDs on the PCB. For a visual comparison

Applications

AOB technology is ideal for:

- Outdoor displays, protecting against weather.

- Rental and staging, handling frequent setups.

- Public places like airports and malls, resisting impacts.

- High-resolution displays, supporting small pixel pitches.

A case study showed an AOB outdoor billboard lasting two years without failures, unlike standard SMD displays needing frequent repairs (details at manufacturer websites).

Comparison with GOB Technology

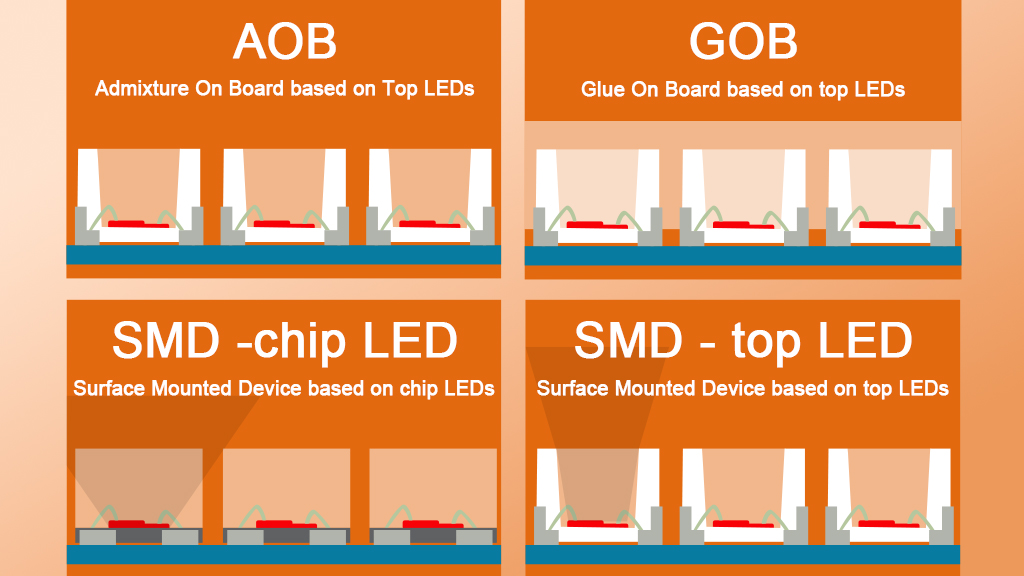

AOB and GOB (Glue on Board) both protect LED displays, but differ:

- AOB strengthens connections between LEDs without covering them.

- GOB covers the entire module with epoxy, offering broader protection but altering appearance.

Technical Specs and Costs

AOB specs include:

- Impact resistance: 6kg side push (vs. 1kg for SMD).

- Defect rate: Below 5 PPM.

- Viewing angle: Up to 170° (vs. 140° for SMD).

- Testing: 72-hour white balance and 24-hour video aging.

Initial costs are higher due to extra steps, but reduced maintenance offsets this. Repairability may be complex, and heat dissipation needs management, though designs address this.

Conclusion

AOB technology revolutionizes LED displays with unmatched protection and quality, addressing SMD limitations. Our standard inclusion ensures reliability, and as technology evolves, AOB will shape future display solutions.