Technical knowledge | Common causes and solutions for LED display lamp bead damage

April 11, 2025

Table of Contents

During the operation of the LED display, the stability of the lamp bead is directly related to the display effect and service life of the screen.

1.Abnormal power supply

- Problem description: The power supply is not working properly or the wiring polarity is wrong, causing the lamp bead to not light up or be damaged.

- Solution: Confirm whether the power supply is started normally and whether the indicator light is on; check whether the positive and negative poles are connected correctly to avoid reverse connection.

2.Voltage and current do not match

- Problem description: Excessive current causes the lamp bead to burn out, especially different colors of lamp beads have different current tolerance.

- Solution: Select a power supply that matches the rated parameters of the lamp bead, and install a current limiting resistor if necessary. Yellow lamp beads are more sensitive to current and should be paid special attention.

3.Determine the luminous color

- Operation suggestion: Use a 3V button battery test to quickly identify the color of the LED lamp bead, which is convenient for procurement and pre-installation screening.

4.High-power LED lamp bead burns out

- Problem description: Excessive current or lack of constant current drive causes the gold wire to fuse and the lamp bead to be scrapped.

- Technical parameter reference: The standard 1W lamp bead current is about 350mA and the voltage is 3.2-3.6V. Three common 1W modules require a 12V constant current source for power supply, and direct connection to 220V is prohibited.

5.The lamp bead turns yellow

- Cause analysis: The epoxy resin and the curing agent do not match, or the packaging baking time is improperly controlled.

- Solution: Select a complete set of packaging materials, standardize the production process, and strictly control the curing time.

6.Lamp bead leakage

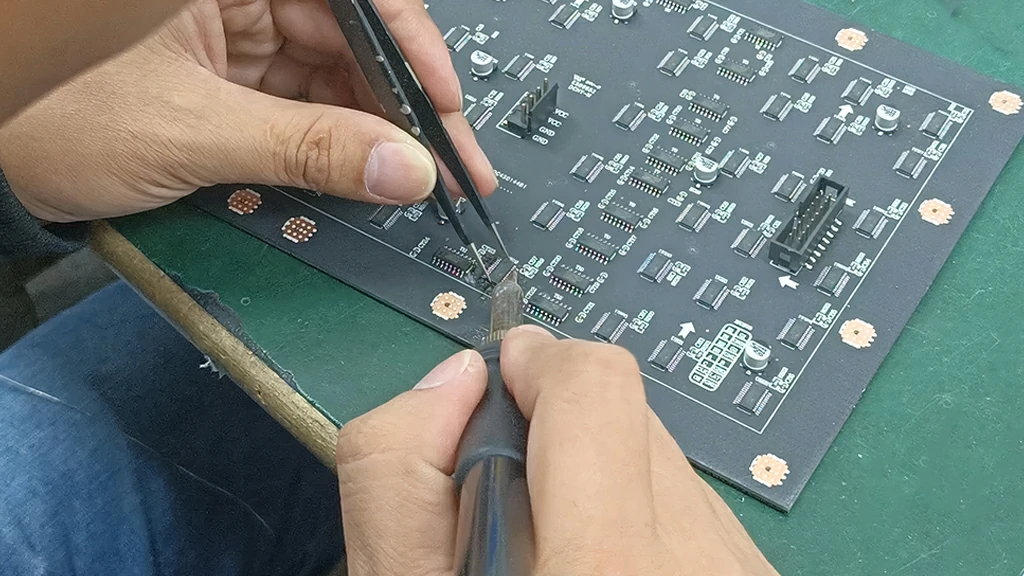

- Cause analysis: The electrostatic protection is not in place, the equipment is not grounded, the operator does not wear an electrostatic wristband, or the chip itself has hidden dangers.

- Solution: Ensure that the electrostatic protection system is in place and strictly implement the ESD operating specifications.

7.LED is a resistive device

- Principle description: LED is essentially a diode, not a capacitive or inductive load. Brightness control is achieved by adjusting the current, and a forward voltage of 2-3.5V is required.

8.Light decay problem Main reasons:

- Poor thermal conductivity structure design

- Yellowing of packaging material

- Poor contact between chip and bracket

- High attenuation rate of chip itself

Coping strategies: Select high thermal conductivity bracket, strong stability packaging material, high-quality chip, and ensure reliable process.

--- END ---